There are lots of terms used when describing the kitchen cabinet building process. Below we have a list of definitions and some sample images to help you better understand this industry terminology so you can be confident you’re getting precisely what you want.

Table of Contents

- Construction Methods

- Cabinet Doors

- General Cabinetry

- Construction Materials

- Joints

- Mouldings

- Solid Woods

Construction Methods

Full Overlay (Frameless)

Full overlay cabinet styles, also known as frameless cabinets, utilize a construction method where the construction of the doors and drawers are built so there is no visible framing layer behind the cabinets and drawers. This gives the overlay-style cabinets a more modern and seamless appearance, versus other styles where a face frame is visible without anything being opened. “Reveals” – or gaps between doors and drawer fronts are typically 3/32”-⅛”.

Partial Overlay

Partial overlay cabinet styles represent a cabinet door or drawer sizing which allows the face frame of the cabinets to remain visible at all times. Door and drawer faces are sized and installed to allow a space between them – anywhere from ½” – 1” or greater – usually on all four sides, which reveals the face frame of the cabinets behind them. This style provides a classic cabinet look and feel.

Face Frame Inset

Inset face frame, or inset cabinetry, is where the construction of the face frame of the cabinets and their cabinet doors and drawers are all flush on the exterior when everything is closed. Instead of the cabinet doors being on the outside of the face frame, they are installed where cabinet hinges and drawer slides are hidden inside of the face frame itself.

Beaded Face Frame Inset

Similar to inset cabinetry where cabinet drawers and doors are flush with the face frame, beaded face frame inset designs provide an additional routed profile surrounding each cabinet door and drawer opening called a bead. This extra outline profile provides a more decorative and complex design, which tends to give the cabinets a more traditional, classic look as opposed to sleek and modern.

Edge Banding (or Edge Tape)

Edge banding is a part of the construction process of full overlay cabinets where the edges of all visible pieces of the cabinetry are worked or covered with a thin applied veneer. The raw edges of cabinets can be unsightly and porous, which could result in moisture absorption – edge banding helps to preserve edges and corners, keep moisture out, and even provide additional aesthetic improvements.

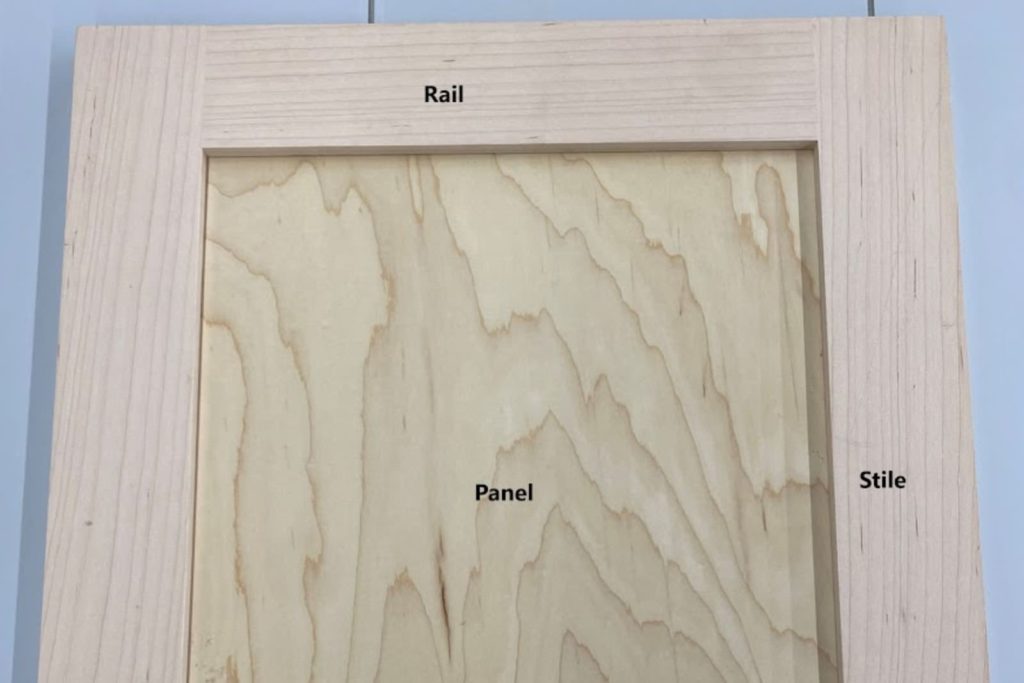

Face Frame

The face frame of cabinets refers to the visible, front-facing frame on which cabinets are built and doors are installed. A face frame refers specifically to the stiles, which run vertically, and the rails, which run horizontally which are mounted on the visible side of the cabinet carcass. Stiles and rails which run through the middle of the face frame are called mid-stiles, and mid-rails.

Cabinet Case (Carcass)

The cabinet case, also known as the cabinet carcass, refers to the box portion of the cabinets and is the framework of the cabinets. The carcass is the major structure of the cabinets which holds drawers, shelves, the face frame (if there is one), hinges and rails. It’s also what you see on the inside when you open the cabinet doors and drawers, and where you would store your kitchen items.

Cabinet Doors

Cathedral

A cathedral styling element to cabinet doors typically refers to the top frame rail and/or top of the raised panel of a cabinet door to have a curved design.

A cathedral double refers to both the top and bottom having a matching curved look, but the side vertical stiles remain straight.

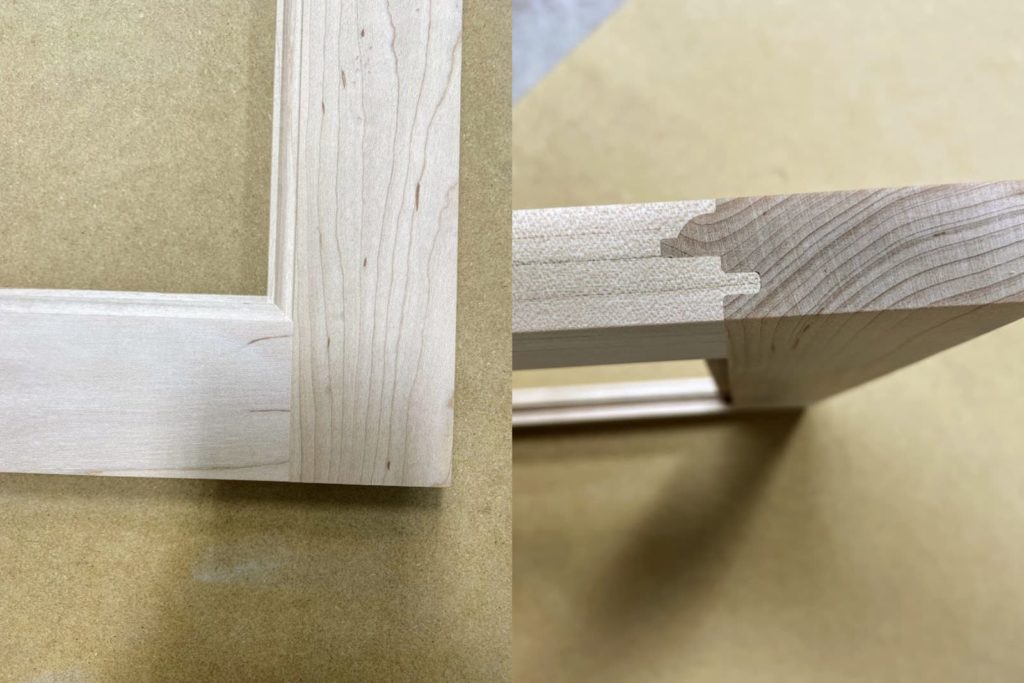

Cope and Stick

A cope and stick style of cabinet door is one of the two main 5-piece cabinet door categories. The main piece of the door, called the panel, has 4 parts of a wood frame around it.

The stiles run vertically, and the rails run horizontally, where the corners meet at 90 degree angles. The frame is built so the panel fits snugly inside the frame, using a tongue and groove fabrication technique, resulting in strength and durability.

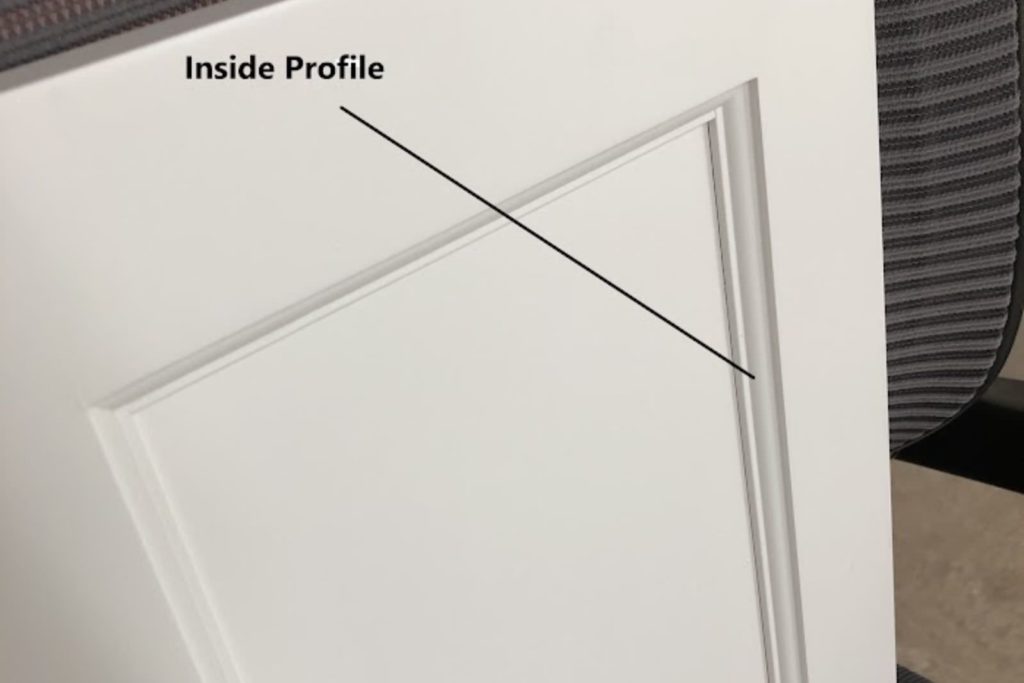

Inside Edge Profile

The inside edge profile of a cabinet door refers to the inner edge of the frame surrounding the main panel.

It can be routed to have a different depth, a different angle, or even different shapes. Where typical frames may be simple and square, the inner edge may have a more decorative or aesthetic.

Mitered

A mitered cabinet door is one of the two main 5-piece cabinet door construction styles. Like a cope and stick cabinet door, it is made of 4 wood frame pieces and a main panel.

The panel is constructed to fit within the frame using a tongue and groove fabrication technique, where the stiles run vertically and the rails run horizontally. Each corner meets at a 45 degree angle.

Mullion

Mullion cabinet doors are crafted where the center panel of the door has moldings running horizontally and/or vertically to divide the look of the cabinet into sections, or panes, like you might see on a window.

These types of doors, popular for cabinet doors with glass, can be used as an accent for a kitchen or bookshelf. Otherwise, the frame style would match the rest of the cabinet doors.

Onlay

An onlay style element is a construction where a slab or flat piece of cabinetry has a decorative piece or frame style built onto the panel itself.

These are common on peninsulas or the backs and sides of a kitchen island, and can create a unique and textured look to compliment the cabinet doors throughout the rest of the kitchen.

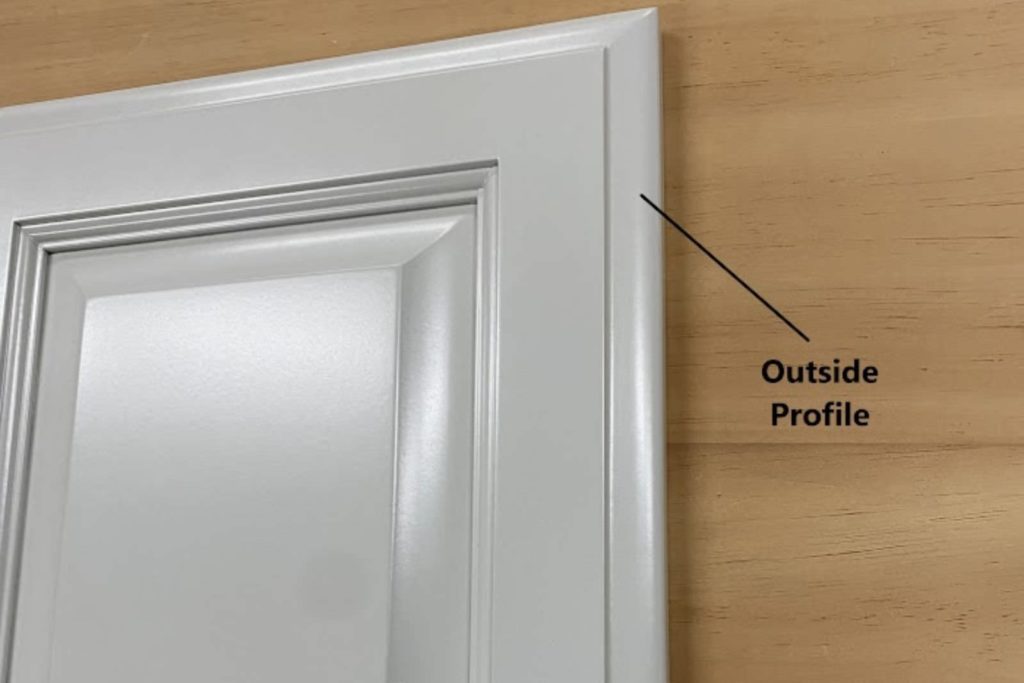

Outside Edge Profile

The outside edge profile of a cabinet door refers to the exterior edge of the frame, or the outside perimeter of the cabinet door.

A standard profile is a square or very slightly rounded edge, but many other styles and edges can be routed. They can be angled, trimmed down, rounded or even have multiple bends or angles to create a wide range of looks.

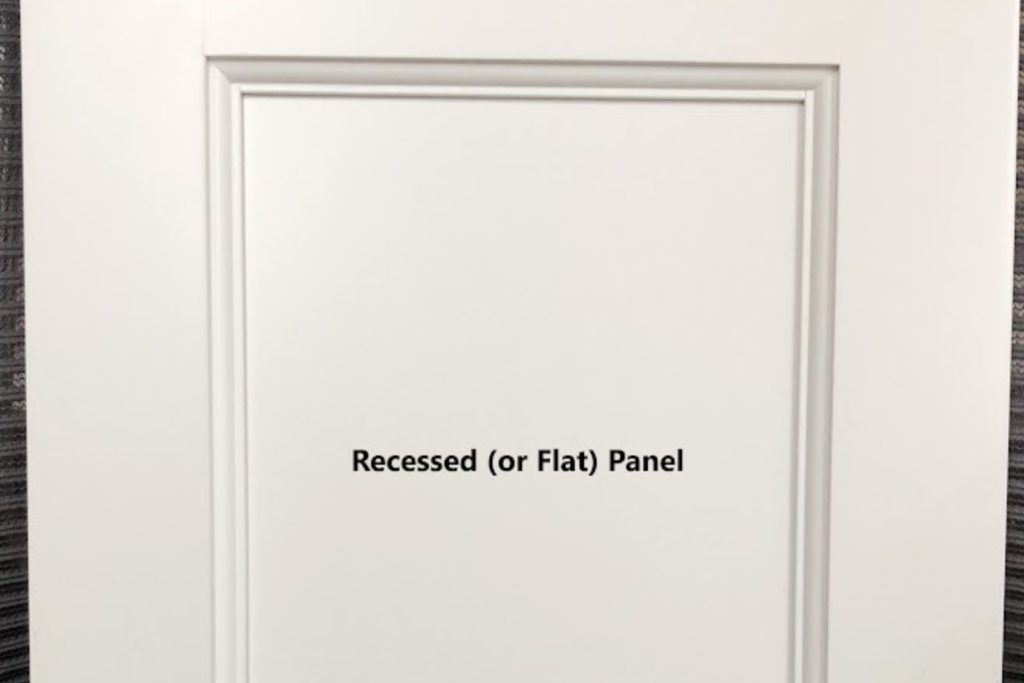

Recessed Panel

A recessed panel cabinet door is a more contemporary choice for people whose preferred aesthetic is more traditional than the very modern and minimalistic “slab style” but also prefer cleaner lines and more simplicity than “raised panel” doors provide.

Recessed Panel doors can be either cope-and-stick or miter construction. As the name suggests, the center panel here is flat and slightly recessed from the face of the wood frame

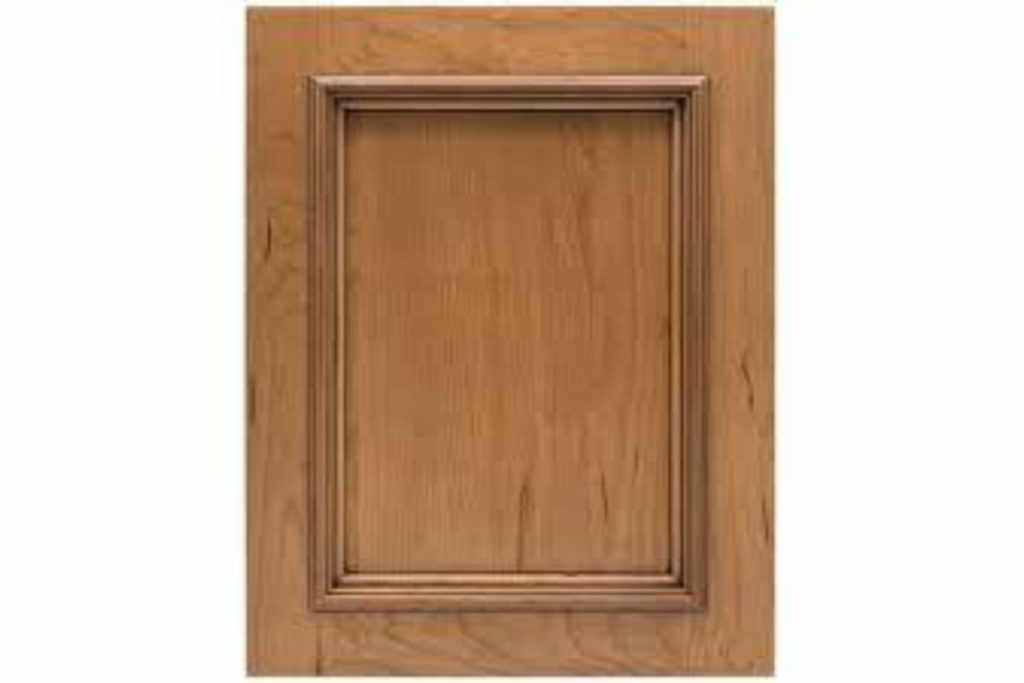

Raised Panel

A raised panel cabinet door is a more formal and traditional look where the center or main panel of the cabinet door is elevated.

Raised Panel doors can be either cope-and-stick or miter construction. As the name suggests, the center panel here is thicker and more decorative than other door styles.

Slab

Slab cabinet doors are perfectly simple and modern. These doors have a completely flat panel with no detailing and without frames.

Slab doors are typically found in contemporary or mid-century modern homes. Made from a solid piece of wood or edge-banded plywood, a slab door is a simple, flat surface without stiles or rails that are seen in five-piece detail doors.

If the door is made out of solid wood, it will require batons which are solid bars of wood attached to the back side of the door. These add support and help prevent the wood from bowing or warping.

General Cabinetry

Applied Door End

An applied door end is typically used on full overlay cabinetry. The end panel is made wider than the cabinet side so the front edge of the applied door end panel is flush with the face of the doors and/or drawer fronts.

Base

A base cabinet is a type of cabinet that sits on the floor and supports the countertop. It differs from wall cabinets which hang on the wall. Base cabinets are typically 24″ deep, and vary by width.

Base Organizers

Base cabinet organizers are lower cabinet storage cabinets specifically designed to add storage of pots, pans, or other common cabinet clutter. They can be constructed to slide out on rails, swing out with a pivot, or even allow hanging of certain kitchen items to increase the efficiency and utilization of base cabinet space.

Blind Corner

A blind corner is a creatively used space where two cabinets are met in a perpendicular fashion, but have no cabinet face. Instead of there being no access in the corner, one cabinet can be extended to the wall adjacent to the other. Swing out doors, a Lazy Susan, or other slide out options can make this normally inaccessible space become extra storage.

Cantilevered “Floating”

Floating cabinets, also known as cantilevered cabinets, are a style of base cabinet build where the cabinets are mounted from an adjacent wall, rather than sitting on the ground. Instead of being constructed to meet the floor, they are supported by a mount or rail which allows the toe kick space to go all the way under the cabinet.

Concealed Hinge

A concealed hinge, or hidden hinge, is a type of hinge used for cabinetry where most or all of the hinge is not visible to anyone while looking at the closed door. It provides a smoother, more continuous look which many people find more modern and aesthetically pleasing. Concealed hinges also usually come with a soft-close option.

Corner Cabinet

A corner cabinet is a special type of cabinet customized to increase wasted space often found where two perpendicular wall mounted cabinets meet. They tend to use a non-standard configuration because the cabinet face and door may protrude from the front to give access to its contents.

Drawer Box

A drawer box is the storage area of a pull-out drawer.

Drawer Face

A drawer face, also called a drawer front, is the visual side of a pull-out or faux drawer which typically matches the rest of the kitchen cabinets.

Exposed Hinge

An exposed hinge is a type of hinge where it is visible, at least in part, while a cabinet door is closed.

Fillers

If your kitchen design has tight spaces and corners, you will likely need a filler. A filler is typically used to finish the space where an overall dimension of cabinetry is less than the overall wall dimension. Most often, fillers are used vertically at the side of a cabinet, but they can also be used horizontally as crown molding risers or trim.

Finished End

A finished end simply means the exposed end or ends of your cabinets will be finished to match the rest of your cabinetry.

Furniture Baseboard with Decorative Toe Cut-Out

A furniture baseboard with a decorative toe cut-out an upgrade option from a standard recessed toe. Specifically, it’s a baseboard which has been cut away to allow for recessed toe beyond—it creates a more “furniture feel” for the cabinetry as opposed to a basic toe kick cut away.

Hood

A wood range hood can provide an elegant focal point to your kitchen. They illuminate your cooktop and ventilate the air of grease, odor and moisture. Wood range hoods come in cabinet-mount or wall-mount style. Both styles can be equipped with a ventilation insert.

Hutch

A kitchen cabinet tower is a countertop cabinet that rests on the countertop, rather than being installed on the wall above the countertop. It offers convenient storage space for kitchen appliances and everyday items, such as serving plates, cups and glasses.

Integrated Panel End

An integrated panel end is a customized look or functional design added to the visible end cut of a base cabinet. Where a typical end might just be a flush look, an integrated panel end can either have designs and details for aesthetics, or even have additional utility like outlets, wine storage or even lighting.

“Panel-Ready” Appliances

A panel ready appliance is most commonly a dishwasher or refrigerator where the front face of the appliance can be matched to the custom cabinetry within the kitchen. This allows the appliance to be hidden and more consistent with the kitchen cabinets, rather than stand out and be a focal point or contrast.

“Proud” (Bump-Out)

A proud, also called a bump-out, is a piece that protrudes, and is not flush with the panel.

Roll Out

Rollouts are a great way to gain more storage space, either in your pantry or as an extra shelf for larger items like pots and pans. Unlike pullouts, which typically have handles that protrude from the cabinet, rollouts feature scoop handles on the inside of the drawer box.

Stiles & Rails

Stiles are pieces of the cabinet door which run vertically, or up and down, usually along the sides of a cabinet door. Rails are pieces of the cabinet door which run horizontally, or side to side, usually along the bottom and top of the face.

Toe Kick (Recessed Toe)

A toe kick is the short area below the bottom cabinet section which, as you might have guessed by the name, is a recessed area for your feet, which basically allows you to stand closer to the countertop without hitting your toes on the base of the cabinets.

Upper

Wall cabinets, also known as upper cabinets, are the wall mounted cabinets installed above the base cabinet. Wall cabinets come in various shapes and sizes to offer different storage options, some of which can be used for display purposes.

Construction Material Terminology

Medium-Density Fiberboard (MDF)

Medium-density fibreboard, or MDF for short, is a type of manufactured wood created from broken down wood and combined with a resin. The broken down wood, which is made from both hardwood and softwood, is combined with a resin and wax under high pressure which compresses and seals the final product to become stronger and more dense than standard particle board. MDF is very smooth as well as stable (less prone to warping) and thus is commonly used as door panels paint-grade 5-piece doors as well as for case material for cabinets with painted interiors or open bookcases.

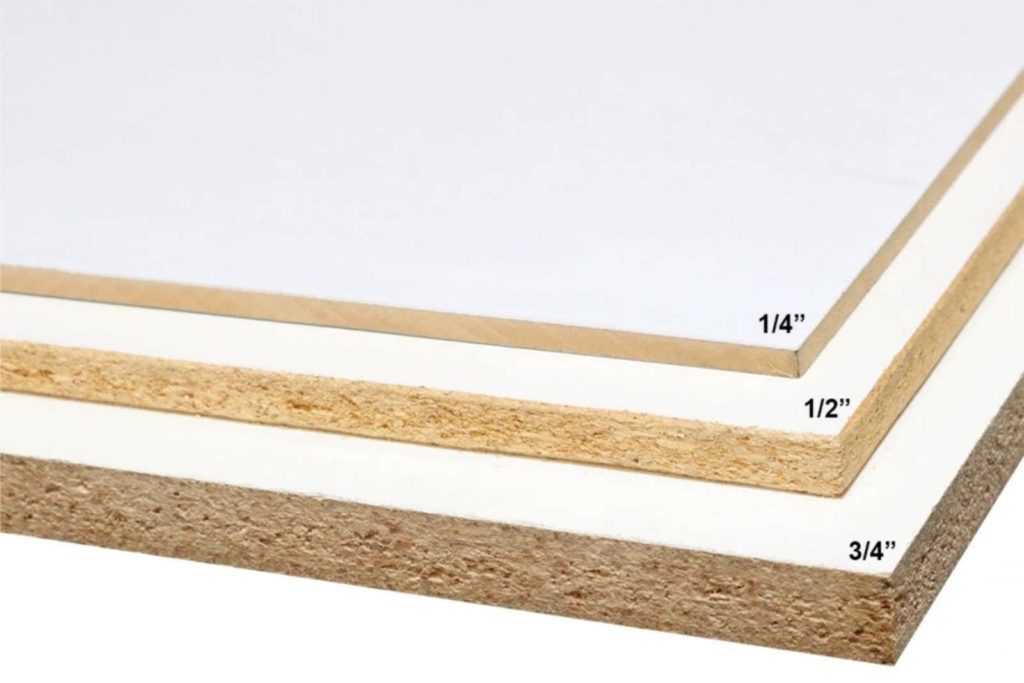

Melamine

Melamine is similar to a standard particle board, but with the extra benefit of being stronger and more durable. A melamine resin, combined with wood fibers, is used to create a low-pressure laminate engineered to be more durable while allowing a much higher quality finish which can be a great alternative to other materials.

Particle Board

Particle board, which also goes by the names chipboard or low-density fiberboard, is another manufactured wood made by combining small wood fibers and a binder, usually a resin, under pressure. While stronger than plywood, it usually has a veneer surface to give it a more appealing appearance, as well.

Plywood

Plywood is a multi-layered material of cross-grained “plies” which are glued together to create a manufactured board which can be made from many types of wood. Each layer is glued together with wood grain being turned 90 degrees per layer, or ply, helping the plywood to become stronger, less likely to bend or warp, and easy to cut or use screws without the worry of splitting. The faces of plywood are finished with wood veneer.

Solid Wood

Solid wood is lumber that has been cut or milled directly from a tree. Although cut, it exists in its natural form and has not been created by wood composites, veneers, or any type of multi-layer construction. Each type of solid wood has its own characteristics, including its grain pattern, color and texture.

Wood Veneer

A wood veneer is a very thin slice of wood which is layered onto a substrate of either plies or MDF. The veneer is typically less than 3mm thick, and is a great way to achieve the look of a certain species of wood for cabinetry cases without the high-cost of solid wood glue-ups. Common species for veneers in custom cabinetry are maple, white oak, red oak, walnut, mahogany, and cherry; but many other exotic species can be sourced as needed for custom projects.

Cabinet Joint Construction Techniques

Dado Joint

A dado joint is created by cutting a groove into one piece of wood against the grain and then fitting another piece of wood into the groove.

Dovetail Joint

A dovetail joint is created by cutting a series of interlocking, wedge-shaped pins into one piece of wood and then fitting another piece of wood into the pins.

Rabbet Joint

A rabbet joint is created by cutting a step at the end of one piece of wood and then fitting another piece of wood into the cut area.

Mortise and Tenon Joint

Used to connect two pieces of wood, the tenon works like a peg and the mortise is the slot or hole the tenon fits into. These joints are known for being sturdy and durable. This is one of the oldest joint techniques in woodworking going back thousands of years.

Kitchen Moulding Styles

Crown

Crown moulding is a type of decorative trim used to cover the transition between wall and ceiling surfaces. Crown moulding is typically installed in strips, with each strip featuring a decorative pattern that creates a three-dimensional effect.

Baseboard

Wood baseboards are boards of wood that are used to trim around the bottom of walls. The boards can be installed to various depths and can feature different styles of decorative trim, depending on the desired aesthetic.

Filler

A filler is typically used to finish the space where an overall dimension of cabinetry or moulding is less than the overall wall dimension. Most often, fillers are used vertically at the side of a cabinet, but they can also be used horizontally as crown molding risers or trim.

Scribe

Scribe moulding is a thin, flexible strip of wood that is attached to the top or side of cabinets. Its purpose is to add a nice finished touch by hiding any blemishes, small gaps, or uneven surfaces between the cabinets and the wall or ceiling.

Applied

Applied mouldings elevate the look of a standard 5-piece door while also providing an excellent canvas for glazed finishes. Available on both butt joint and miter joint wood doors, applied moulding pieces are securely attached to the front of the doors and 5-piece drawer fronts.

Solid Woods

Glue-Up

The process of bonding two or more pieces of wood together using glue. The glue-up process involves applying a layer of glue to the surfaces of the wood which will be joined, clamping the pieces together to ensure a tight bond, and allowing the glue to dry. Once the glue is fully dried, the clamps can be removed and the wood can be sanded, finished, and used as desired.

Grain

Grain, or wood grain, is the most common name for the pattern, the lines, the texture, or even the porous cells of the wood material. Wood grains run longitudinally across the length of a board, and each pattern or grain is entirely unique, like a fingerprint, to the tree the board came from.

Hardwood

Hardwood is any wood or board sourced from trees which bear flowers and leaves, like oak and walnut, for example. Other most common hardwoods might include maple, birch, cherry, and poplar. These all tend to be from trees which grow quicker than softwood.

Live Edge

Live edge wood refers to wood that has been cut and finished in a way that retains the natural edge of the tree. This means that the bark, knots, and other natural features of the tree are left intact, giving the wood a unique, organic look. Live edge wood is typically cut from trees that have fallen or been cut down, and is often salvaged from forests or urban areas. It is then dried, planed, and finished to retain its natural beauty.

Rough Lumber

Rough lumber is wood that has been freshly cut from a tree and has not yet been smoothed or finished. It is often used in construction and other applications where it will be further processed before being used in a final product. It is typically less expensive and easier to work with than finished lumber.

Sizing

When discussing sizing for wood, they are always stated in this order: thickness X width X length. In addition, wood sizing comes in both nominal and dimensional size descriptions. Nominal sizing is the actual rough cut of the wood, where dimensional refers to the final size of the board after being planed—therefore, the final dimensions might not be the same as the stated board size.

Softwood

Softwood is any wood or board sourced from coniferous trees, or trees which don’t bear leaves, like cedar or pine. Other most common softwoods might include Douglas fir, redwood, white pine, and southern pine. Softwood tends to take longer to grow than hardwood.